So what's happenin' Dude? I hear you ask.

Well, I almost had it running - but you've heard that story before? no - really!

My careful measurements of the power required to drive the engine from an external motor as I brought the fuel flow up have convinced me I'm on the right track.

The plot of power versus temperature exactly parallels the theoretical calculation.

Except for two effects.

The predicted relation is a straight line but I found I was getting a curve that showed power being lost in two ways:-

One was at startup. The effort required to spin the engine cold is much greater than expected. I put this down to the effect of oil viscosity.

As an aside, it's amazing how fine the operating point of the turbine is - If losses exceed gains by even the smallest part of a watt the engine won't run.

If gains exceed losses by just as much, the turbine can accelerate out of control in seconds.

Despite the massive power potential, the friction losses resulting from a few grammes of resistance observed at the turbine diameter make the difference between life and death.

The second effect is a similar frictional loss that appears at high temperature - I have no idea what is causing it. It's tiny - I can barely feel it when turning the shaft by hand - but it kills the engine stone dead.

I said I almost had it running?

Yes: With the engine being driven flat-out by my blower and pushing the combustion temperature right up to the limit, I reached a region where the engine definitely tried to run.

No doubt in my mind at all. It suddenly accelerated, becoming very sensitive to the amount of fuel being fed in - for a moment I thought I had lost control from the way it accelerated. But then effect #2 kicked in (I think) and the engine slowed again -then picked up - and slowed again.

After a few such spurts, I decided to stop the test because the turbine wheel and NGV were glowing brightly and I know where that leads! (See last post)

Anyway - Got to find the cause of that friction.

Wednesday, 23 April 2008

I got it! I got it! - - - I don't got it! (groan)

Posted by

Anthony

at

07:55

16

comments

![]()

![]()

Thursday, 20 March 2008

Oops!

After getting some advice, I decided to remake the Combustion Chamber.

The old one wasn't working properly, the gas mixture appeared too rich, with yellow flames visible at times.

So I made this one, with much smaller air-holes.

I think the theory is that the air is forced to move faster through the smaller holes, giving more turbulence and better mixing.

Anyway, it seems to work.

The flames are much bluer-whiter and the turbine seemed to have more shaft power.

I say 'seemed' because I got carried away with the throttle setting in an attempt to reach maximum speed and before I could measure anything the back end of the engine suddenly vomited a shower of flame and molten metal fragments!

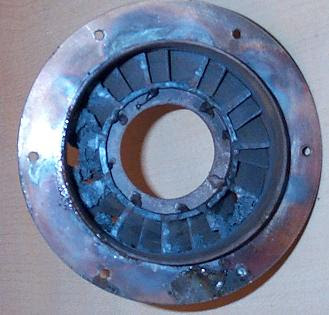

Here's what's left of the NGV assembly. It appears that several of the stainless steel blades melted and exited through the turbine wheel.

Fortunately, they melted so completely that the turbine itself was undamaged (after I scraped the gobs of molten metal of it!)

That's despite the fact that it stopped so suddenly that the drive shaft (which continued to rotate) unscrewed itself completely and continued to spin.

It's going to be a few days before I finish making a new one.

The new NGV under construction

Posted by

Anthony

at

09:26

0

comments

![]()

![]()

Thursday, 13 March 2008

A carbon fibre compressor impeller

Click the picture for a larger view.

Just to let my readers know that I haven't given up and gone away ;-) I'm posting this composite picture of the stages in making a CF impeller.

The reason it's been a while since I posted is that I'm remaking the entire engine compressor section and some of the parts take a while to make. The impeller in particular. It doesn't take long in terms of time spent, but the bonding/glueing processes take 24 hours at each step.

The process starts (frame 1) with an aluminium boss shaped on the lathe with a nice smooth 'conical' curve to help the airflow. A similarly shaped laminar plate for the coverplate is made in CF (two layers). In the shot you can see the two parts of the mould I used for this job, turned out of a bar of nylon.

Frame 2 - The boss and cover are slotted to take the curved blades. The slots are started using a 'Dremel' tool router bit (0.8mm). I roughed them out using a piercing saw then finished them with the router bit, this time using a pillar drill at high speed.

Frame 3 - The blades are cut from a sheet of 2 ply CF. I make this sheet by laying up two layers then clamping them between boards. (I've found the use of peel-ply to be very helpful in all of this work but it produces a rough texture that I try to avoid on the 'airside' surfaces by using polythene sheeting. - one side of the sheet is rough(peel ply), the other smooth (poly).)

After cutting, I glue the blades into the boss and leave to set.

Frame 4 - The fiddly bit! The cover plate has to be persuaded to fit over the blades and eased down to be parallel with the base boss. A spacer is inserted between the two parts and helps a lot with setting the plate correctly.

I could probably get more accuracy using jigs here but the end result is acceptable for the prototype.

Frame 5 - After glueing and hardening, the blades are trimmed down to the cover plate (using the Dremel again and finishing with a spin in the lathe using glasspaper) and then (Frame 5) a final layer of CF is bonded over the cover plate.

Frame 6 - The impeller is mounted in the lathe and the inner orifice is roughed out allowing the spacer to be removed.

All that remains is another layer of CF to be bonded over the bottom of the boss for added strength and the whole thing can then be trimmed to size and polished up.

Posted by

Anthony

at

07:12

1 comments

![]()

![]()

Saturday, 1 March 2008

Finally! - some help

I posted a query on the DIYGasTurbines group at Yahoo and got some helpful advice.

(Thanks guys)

It seems I need to really 'push' this thing - as much starter speed and fuel as I can - push it right up to the highest speed I can get.

Before anyone get's excited - I didn't get it going, but I think I got a lot closer and identified a couple of problems.

Taking it up to maximum speed on the big blower and opening the throttle (carefully) to the max, I got over a foot of water pressure in the casing - 0.03 bar. I had taken the tacho off in order to get a better airflow into the intake so speed is unknown - although that pressure corresponds to about 30,000 rpm.

When I tried to remove the blower, I got a huge roaring, drumming sound from the front that I could feel in the air around the air intake. I believe this is compressor surge. In which case, the impeller is unable to handle the back-pressure from the engine, leading to a rhythmic stall-and-recover from the blades.

In a way it's good news. It means the compressor is close to the working region.

I'm going to rebuild the front of the engine, impeller and diffuser, to a slightly different design to give a smoother airflow.

Posted by

Anthony

at

01:59

0

comments

![]()

![]()

Wednesday, 27 February 2008

If it doesn't work, fiddle with it...

'Spinning up' the turbine with an air blast is a pretty effective way to start it, but when it comes to making careful measurements, the fact that something is forcing air into the engine gives a problem.

I can't tell if the compressor is adding anything to the airflow. Certainly the speed increase I get when burning fuel would be accounted for simply by the heat expansion of the air being forced in. (About a factor of three in temperature gives a factor of three in volume - equals a factor of three speed increase)

So: I dug a small electric motor out of the junk box and mounted that to drive the turbine shaft via a rubber band/pulley.

With the engine spinning, I now had only the air being supplied by the compressor and could watch the effect of burning fuel inside the combustion chamber.

When the fuel was ignited there was a distinct and measurable increase in speed as the turbine started to generate it's own power and 'help' the electric motor.

The increase in speed was significant: from 4500 rpm cold, to 7500 rpm at the limit where the NGV begins to glow bright red.

So I'm definitely getting a power increase. Question is: How much?

Observation

It's interesting to note that power is still being supplied after the fuel gas is turned off. The combustion chamber remains hot for some time and continues to heat the air, supplying power to the turbine. Speed gradually returns to the original 'cold' value, but it takes a couple of minutes.

Another motor

Repeated the experiment with a different, more powerful motor. I geared it up so that the motor was heavily loaded and wouldn't max out in terms of revs (that's important - once the motor begins to reach it's own speed limit, internal resistance begins to dominate).

This time I got 7,500rpm cold and 12,000rpm hot. At these speeds the compressor was supplying a lot of air - I could open the gas bottle tap much further before the exhaust reached red-heat. Interesting that the ratio hot speed to cold speed is about the same (1.6 : 1). It's probably telling me something... but I don't know what.

The test self-terminated when the rubber band broke.

Posted by

Anthony

at

06:35

0

comments

![]()

![]()

Sunday, 24 February 2008

Another way to test the compressor

Bloody infuriating!

It still refuses to run -just!.

Once I get it spinning and ignite the gas, I can back off the hairdryer until I am standing two feet away, just playing the wimpy little hairdryer on the air intake from that distance. The engine keeps running with just that gentle draught, but if I switch off the hairdryer it slowly winds down.

Now I've run out of propane and have to wait for a delivery.

Later that same day...

It occurred to me that since I know how much airflow it takes (1 hairdryer's worth) to spin my turbine at a particular speed (4000 rpm close-up), if I spin the compressor at that speed, in a perfect engine I should be able to get the same airflow. (In a perfect engine, the massflow produced by the compressor would be precisely equal to the that required to spin the turbine - it's a perpetual motion thingy)

Obviously, the engine isn't ever going to be perfect, but I'll get a figure for the relative 'goodness' - an overall efficiency figure.

So I removed the turbine wheel and set up an electric motor to drive the engine shaft at 4000rpm Then I taped a big plastic bag over the exhaust and switched on the motor.

It took 30 seconds to completely inflate the bag. Motor speed was a little higher than I intended (about 4500 rpm), so call it 35 seconds to compensate for that.

Then I repeated the experiment, using the hairdryer shoved up the air intake instead of the electric motor.

That took 15 seconds to inflate the bag.

So the compressor supplies a little less than less than half the airflow that would be required to make the engine perfect.

That's not as bad as it sounds, an overall 50% efficiency figure would actually be acceptable. If the turbine and compressor are 70% efficient each, that's the resultant efficiency you get (70% of 70% is 49%). According to the books, those are typical figures. It looks as if my gut feeling that it's almost there is bolstered by the measurement - it comes out at 43% in this case.

Dimensionless constant

In turbo theory there is a number of formulae, used for describing compressors and turbines that are known as 'dimensionless'. This is because they correspond to constants in the theory, which can be used to compare and model different designs.

One of these is the 'supply coefficient', which defines the perforance of a compressor in delivering a flow of gas.

It's defined as the radial flow divided by the rotational speed and it's a constant for a given design. Turbocharger compressors typically have values from 0.26 to 0.30

Schreckling gives figures in his book which allow the value of the supply coefficient (Sc) for his compressor to be calculated. It comes out as 0.23.

Sc can be written as : volume flow/(rotational speed * wheel diameter3)

In Schreckling's case, that's 0.1/(1250 * 0.073) = 0.23

I measured the volume of my plastic bag and it came out to 0.1 m3.

I also did several more runs at different speeds and came up with a consistent value of 60 seconds to fill the bag at 33 revs/sec [proportionally, at 132 rev/sec it was 15 seconds].

So my supply coefficient is 0.1/(60*33*0.063) = 0.23

It's absolutely spot on!

Posted by

Anthony

at

10:35

0

comments

![]()

![]()

Thursday, 21 February 2008

Schreckling style compressor

One thing that isn't mentioned anywhere in the books I have is the question of blade length.

Although the diameter of the impeller is involved in calculation of the ultimate pressure and the blade angle also is taken into consideration, there is no mention of the importance of the blade length. (Even the number of blades is mentioned as a design factor)

Obviously though, the length of the blade is going to have an important effect on the airflow. (In the limit, a zero-length blade will not work at all)

Looking more carefully at the compressor design in Schrecklings book, I noticed that the blades are pretty well as long as possible. And looking at the design of turbocharger impellers, I can see that they are made with blades that extend forward along the axis, making them much longer than they would otherwise be.

The blades of this Mitsubishi wheel are at least twice as long as my own design attempt.

This photo was taken before I trimmed the wheel to size and opened out the inlet, reducing the blades even more.

Anyway, I made a new wheel, based as closely as I could on Schrecklings design but in Carbon Fibre. (Photo later, just now it's in the engine, cooling on the bench)

When I installed it and ran the engine up, there was a distinct improvement in response. Still not self-sustaining but about 20% higher ultimate rotational speed for the same fuel input.

Unfortunately, something is tightening as the engine heats up to operating point. It frees as soon as the engine begins to cool but it's stopping me from making any real observations. That, and a hot spot in the combustion chamber, clearly visible in the exhaust need to be addressed before I can go any further.

Later

Found the cause of the tightening. The rear bearing hasn't quite enough axial play. There's a temporary packing between the turbine wheel and rear bearing that shouldn't really be there but I was using it to adjust the position of the wheel with respect to the NGV. When I removed it, the tightness went away.

Some figures. When cold, the engine rotates at 15ms per rev with the hairdryer pushed against the intake (4000 rpm).

Running, with the NGV glowing bright red - estimated 700 degrees C, the speed is 6ms per rev (10,000rpm). So that's an increase of 4:1 in speed for an (absolute) temperature rise of 990/290 = about 3.4:1, suggesting that some at least of that speed is attributable to an increase in massflow as the compressor spins up.

I could be off in my estimate of the temperature but to account for a 4:1 speed increase on temperature alone (without an increase in massflow) would require a temperature close to 900 degrees.

Posted by

Anthony

at

05:59

0

comments

![]()

![]()

Friday, 8 February 2008

New Compressor

Compressor test rig revisited

Completely remade the compressor wheel and diffuser assembly. Put the whole thing together... and the difference? None!

It's really wierd that whatever I do seems to make no difference.

Well, no, it isn't really. The problem is that faced with a lump of engine that doesn't work I don't have any feel for what might be the problem. If it were a piston engine, there wouldn't be a problem but the jet turbine is something where I have no experience to go on.

I keep coming back to the fact that I don't have any facts or figures that relate to the actual engine. Calculations show that at such-and-such a blade angle and such-and-such temperature, the turbine wheel should generate yeay watts of power, compressing so many kg of air per second to such-and-such pressure. But there's no way to tell if it actually does.

Anyway, I do know that there is something wrong with the combustion. So I've worked out a way to drive the compressor section from an electric motor and run the combustion chamber in the airstream.

This avoids having a blower just blast air into the engine which doesn't tell me anything.

I've been trying to do this before by driving the shaft directly from a motor, which had to be placed right in the exhaust (putting it at the front reverses the sense of rotation and runs the compressor backwards).

For obvious reasons that wasn't too good. The motor was in the way when looking up the pipe and had to be on a long shaft to get it out of the exhaust. The long drive vibrated and shook the engine/motor, affecting the alignment and causing speed variations. Igniting the engine caused the shaft to expand, creating friction that had me on a wild-goose-chase for a while.(It looked like the bearings were starting to lock up when hot.)

Then I hit on the idea of driving the engine from the side using pulleys. It works fine!

The shot above shows the compressor running with the engine lit. I get a beautiful clean blue burn with the flame 'locked' in the fore-part of the chamber even at full pressure from the gas bottle.

Now I have to think about what this allows me to measure.

Update

With the motor driving, I get a clean, blue burn. I reassembled the engine with the NGV and turbine in place, then tried again.

The motor drive spins the compressor fast enough to produce the same clean burn but the moment I take off the drive the combustion collapses into yellow.

Is it possible that I'm not getting enough power from the turbine wheel? When I shaped it, I left the blades rather thick - almost 3mm at the tips. Maybe that is affecting the turbine power.

Update - 12th Feb

Reshaped the turbine blades, making them much lighter and about 1mm thick. Also added extra vanes to the NGV assembly to smooth the airflow further.

Still no improvement.

A bit of foreign material got into the compressor so I had to strip it down. On checking measurements, I find that the wheel is rather thicker than I designed it for. Because it is broadly conical in shape, when I trimmed the diameter it widened out the blade tip height to almost 10mm instead of the 8 I was aimimg for. Since my calculations show an ideal height of 6.5mm, maybe I have gone too far?

I'll make a new one.

Posted by

Anthony

at

11:26

0

comments

![]()

![]()

Sunday, 3 February 2008

Much thought later...

I've reached the conclusion that my compressor is too 'thin'.

Although it reaches the required pressures, it doesn't deliver enough volume of air.

I've tried to calculate the dimensions but this is an area where the treatments presented in both Kamp's and Schreckling's books are very vague. Although there are several pages of math, when you read through them carefully they make little sense. The symbols used don't always correspond to the diagrams and formulae are often presented without proof or reference.

I suspect the translation in both cases, there's no excuse for swapping subscript symbols between 'th' and 'w' in mid-argument. But it's just the sort of typo you would get if the editor didn't understand the subject.

Whatever; Although it's possible (with difficulty) to calculate the blade height for the compressor wheel from the shaft power and other dimensions, the result relies so much on assumptions as to be almost useless.

The probable error due to 'unknowns' in the calculations is wider than the operating tolerance of the engine.

I will have to experiment. Unfortunately, that means I will have to remake the entire diffuser assembly too.

Mine is 6mm. I will try making one about the same as Schreckling's.

Still, it's a chance to use that aluminium ingot I made.

Posted by

Anthony

at

00:56

0

comments

![]()

![]()

Tuesday, 29 January 2008

Gas velocity measurements

The blower I made from an old vacuum cleaner is quite powerful, in fact it gives a noticeable thrust on it's own.

By mounting it vertically on one end of a balance (a length of Al shelf support) and hanging a known weight on the other ( a 1lb hammer) I was able to get an estimate of the thrust.

That came out as 0.62 Newtons.

Knowing the diameter of the outlet (45mm : 0.0016m2), I calculate massflow to be 0.035kg/sec, which corresponds to a velocity of 18m/sec. (Volume flow is 0.029 m3/sec )

This piece of information gives me a handle on a couple of things that I have been trying to find out

Turbine behaviour

The turbine cross-section area is also 0.0016 m2 (happy coincidence) so velocity at the turbine should also be 18m/sec also when the blower is used to drive the engine cold.

This corresponds to a calculated peripheral velocity of 26m/sec and angular velocity 10,000rpm (NGV and turbine blade angle both 35o).

This calculated speed is in good agreement with that measured, when the blower is placed directly against the air intake. (Chamber pressure measured : 1.0026 bar)

N.B. A small 'flag' held aft of the turbine shows no residual rotation of the airflow.

This gives me a lot of confidence in the turbine itself.

Pitot tube

Fed the blower output into a 50mmm dia pipe (0.00196m2). That gives an expected flow velocity of 0.029/0.00196 = (about)15 m/sec

Using a couple of pieces of small diameter plastic pipe (3mm), I measured the 'ram' pressure with my water 'U' tube manometer. It came out at 1.4 cm H2O which is equivalent to 1.4 millibar.

1.4 millibar is 1.4*101.325 = (about)140 Pascal (ie kg per sq m)

Bernoulli states that pressure = density * v2/2

so v2 = 2 * pressure / density = 2 * 140 / 1.2 = 233

so v = 15.275 - which agrees well with the expected value.

This means I can measure flow speed reasonably accurately using a simple manometer.

That's a bit of a breakthrough.

Measurement of the airflow at intake and exhaust gave the same figures but restricting airflow to give different velocities gave results that suggested that the volume flow rate dropped with the restriction (which makes sense)

Consequences

I have a motor that I can use to drive the compressor at about 15000rpm.

If the turbine were actually working and turning at that speed, the massflow should be 0.017 kg/sec. (calculation not shown - from my spreadsheet)

So if I connect a pitot tube to the outlet of my test rig, I should be able to examine the behaviour of the compressor with that goal in mind.

Posted by

Anthony

at

07:36

0

comments

![]()

![]()

Monday, 28 January 2008

What Now?

In Schreckling's book, there is a photo of the first jet turbine he made run.

The compressor section is really simple, without any diffuser vanes at all. It's nothing more than an impeller running in a plywood case with four pipes taking air to the combustion chamber.

That compressor couldn't be significantly better than mine. If that engine ran, so should mine.

It occurred to me that I haven't been bothering to set up a mirror to look at the spinning turbine. So I did another run.

That showed me something I had missed. With the turbine spinning, I can see up past the tips of the NGV into the combustion chamber. I didn't like the colour of the flame in there. It had far too much yellow in it, especially as the gas supply is turned up. Not enough air.

There is also a dramatic change when the air blower is removed and the engine begins to wind down. The amount of yellow increases immediately and the flame moves towards the exit of the combustion chamber.

I drilled some more holes in the front section of the Combustion Chamber(CC), which seemed to help.

Unfortunately, one of the injector needles got damaged during the next assembly. I need to replace it but I've run out of oxygen for my brazing kit.

We'll be back after these messages...

Well, I replaced the broken needle, widened some more holes and tried again. Better but not spectacularly so.

I stripped out all the internals and just left the CC in place to have a look at the burn. Here's a picture.

For this shot, Ive removed everything except the CC itself and shoved my big blower in the air intake. So I know exactly how much air is entering the casing and how fast.

It's difficult to photograph this. I used a mirror. The two red glowing lines are wires that hold the chamber parts together. There is a dark spot bottom left but otherwise it's a really clean burn.

You can see the tips of the injector sticks glowing bright red (there are 8 - some hidden by the angle). The dark spot is caused by two of the injector sticks being slightly off-angle. When I adjusted them it disappeared.

Next, I put everything together but left off the turbine wheel and instead conected a motor to drive the turbine shaft. I had to use a long driveshaft to keep the motor out of the exhaust.

Here's a shot of the test. The motor is running and the flame is lit. You can see the flame inside the combustion chamber through the NGV assembly - It's quite yellow, indicating not enough air.

Attention focusses once more on the compressor...

I have to go back to the test rig and see if I can't 'tweak' it to give more information.

Posted by

Anthony

at

00:57

0

comments

![]()

![]()

Sunday, 13 January 2008

Testing Compressor designs

There's no way round it, I need to know what makes a good compressor and what makes a bad one. There's lots of stuff in the books about thermodynamic calculations for establishing diffuser vane angles etc., but most of it is just hindsight justification of a proven design.

I need to know exactly how important are the various parameters, such as blade angle, inlet and outlet diameters. Does it matter if I set the diffuser blades at 19 degrees instead of 20? If I increase the impeller diameter by 1mm does it make things better or worse?

This is the setup I made for testing compressor designs.

The casing is just a steel tube, same size as I use for the engine casing. The front is a mockup of the engine internals made of MDF.

You can see one of the test impellers (pink GRP) mounted on the end of the drive shaft. There is no diffuser assembly in this test configuration - I just want to get a base value (worst case) for the behaviour of the compressor.

At the rear of the test rig is a motor, mounted on the end plate. (MDF again). Note the ring of holes in the rear plate that allow compressed gas to pass out of the chamber. These holes can be progressively closed off using plugs, to give a measure of the pressure obtained at different mass flow rates. The number and size of holes roughly appproximates the engine flow cross-section 10sq.cm.

A simple u-tube manometer is connected to a nipple on the rear plate (not visible in this shot) for pressure measurement.

Results

This first impeller is a simple plano-parallel configuration 60mm OD and 30mm ID.

Blade height is 7mm.

The motor turned the impeller at 15000 rpm and the measured pressure as each hole was plugged was as follows. (Two runs)

Note that 1mm of H2O = roughly one millibar of pressure.

Conclusions

Not as expected.

In theory, the compressor should 'stall' as the mass flow is reduced to zero, resulting in a drop of pressure at the closed-off end of the graph. In other words, there should be a maximum somewhere in the curve. But this test shows a steady increase in pressure as the flow was closed off, resulting in a maximum pressure differential of 100 mbar when fully closed.

Perhaps this is due to the lack of a diffuser assembly?

An alternative explanation is that running at relatively low speeds (20,000 rpm is considered idling) means that the airflow is stable and doesn't stall over the blades even at extreme back-pressures.

Later: -

I inserted a diffuser assembly and tried to repeat the expt. but I experienced trouble with the speed/pressure oscillating when the holes were closed off. Is this the 'surging' mentioned in textbooks? It was very pronounced, even though there didn't seem to be a big improvement in pressure generally.

Unfortunately, the stickytape-and-string diffuser fouled the impeller and destroyed it. I'm going to rebuild a slightly more convenient test rig (I'm having trouble getting it apart to adjust/replace the innards. )

Much Later: -

I redesigned the test rig to make it more convenient to change the impeller and or diffuser.

In this shot of the new rig you can see a test diffuser assembly on the table in front of the test rig. It's just a supporting ring of GRP with a set of vanes glued to it, Quick to make and install.

To cut a long story short, I ran a series of tests on different impellers using curved, angled, and compound blades (ones with a 'lip' to act as a primary axial impeller).

The results were frustratingly consistent. The only things that made a significant difference were the impeller diameter and shaft speed. Otherwise, the ultimate pressure obtained was the same, whatever the blade design.

The motor speed was the major factor. the pressure rises exponentially with speed so that a small change in motor loading (blade width or shape) causes a speed change that hides any effect the blade shape might be having directly on airflow.

The 'surging' effect I had noticed disappeared - I put it down to varying load on the motor causing a speed change resulting in a feedback effect.

Now what? I've run out of ideas.

Posted by

Anthony

at

08:16

0

comments

![]()

![]()

New tests

Looks good doesn't it?

Still doesn't work.

But I feel it's SO close...With the starter fan helping, I've had this engine up to 25,000rpm today.

Blew the water right out of my home-made manometer! Well over a foot of pressure.

At 18000 rpm the casing pressure is 6 inches of H2O (corresponds to 1.0150 bar)

Since I also know that the compressor is capable of delivering 5 inches of H2O at 18000 rpm,

I am optimistic that if I can just squeeze another drop of efficiency out of the compressor, I will have a working engine.

It's literally just an inch away!

I've taken to running indoors now, It's a matter of balancing the risk of an accident with the engine or gas supply against the English weather. It's wintertime. It never gets desperately cold in England in winter

but we have our own special brand of cold rain, wind and sleet that's kept these islands free from invaders for a thousand years..

(No one else is daft enough to want to live here.)

Posted by

Anthony

at

07:43

0

comments

![]()

![]()

Nozzle guide vanes

An awful lot of work goes into the NGV assembly and since it involves a lot of cutting, bending and welding of thin stainless steel parts, at each stage the stakes get higher.

The penalty for a mistake is hours of work reduced to twisted scrap in a microsecond.

But that's half the fun isn't it?

Here's a shot of the inner and outer rings of the NGV. The curved blades have been inserted into slots cut in the inner ring using a jigsaw.

(I removed the footplate and used it freehanded as a reciprocating saw. Nasty, juddery experience, but it worked)

After welding, the blades were very gently machined down in the lathe to fit the diameter of the outer ring.

I left a little tag on each to locate into short slots cut into the outer ring.

The NGV assembled and ready for final welding. The central web has just a small hole in it at the moment, that will be opened out to provide location and support for the turbine shaft tunnel

I discovered it's more than normally important to work slowly, tacking the parts together at opposite diameters and letting it cool after each weld to avoid the assembly distorting.

The first time I made one of these I only just got away with it. The turbine housing (outer ring) finished so far out of round I amost didn't have enough thickness of metal to true it up.

Since the turbine wheel itself is supposed to howl round in that bit of pipe with a clearance of just 1/4mm (10" thou.) It's vitally important for it to be absolutely round and concentric with the shaft tunnel support.

This time, I checked the alignment in the lathe chuck after each tiny tack-weld.

Posted by

Anthony

at

07:36

4

comments

![]()

![]()

A new turbine wheel

I managed to get hold of some nice stainless steel round blanks 6mm thick and 66mm diameter - just perfect for the turbine wheel.

First step was to drill out the centre and remove some of the thickness from the blank around the middle of the wheel.

The hole in the middle is a potential weakness in a high-speed rotating component, thinning out the mid section of the wheel reduces the spinning mass without sacrificing too much strength.

After boring and thinning, I used a metal-cutting bandsaw to slot the blades.

Each blade was then twisted - I was aiming for an angle of 35degrees but the bandsawn slots weren't wide enough - I guess the final angle here is about 25 degrees.

I started out heating the blades to red-hot before twisting but ran out of gas after a couple. It didn't matter, as it proved perfectly possible to twist the blades without heat.

Note the tool I made for the job, it's mild steel, about a foot long.

I had to make a mandrel for the wheel in order to mount it in a vice - Just a couple of pieces of scrap aluminium and a bolt through the middle.

Now the frightening bit.

With the wheel clamped firmly in a vice, I used a hand-held grinder (125mm cutting disc, 4mm thick), to cut down between the blades, reducing each to a crude faceted-airfoil shape. (see diagram below - looking down on the edge of the wheel, I cut almost straight down but followed the blade edge to produce a thin tail to the airfoil)

The grinder is a heavy and powerful tool, designed for brute force rather than delicate work. I had to brace myself firmly and wear full polycarbonate face armour, dust mask, gauntlets and leather apron against the sparks.

I had to fight to hold the monster steady, It felt like cutting my toenails with an axe, but the end result was surprisingly neat

Final shaping was done by grinding with a 'Dremmel' tool.

Each blade is shaped to an airfoil section with the front of the airfoil blade making an angle of about 80 degrees to the disc. The blade is curved so that the 'tail' is nearer to an angle of 35 degrees and the underside of each is as evenly 'scooped' as I could get it (working between the slots there isn't much room for the cutting wheel).

Ain't it pretty?

Posted by

Anthony

at

07:30

0

comments

![]()

![]()

A new beginning

I decided to follow the construction plans for Thomas Kamps engine given in the Modellers' World book with a few modifications to allow me to use my own compressor impeller and turbine.

By now I'm beginning to regard making a complete new engine as just a couple of evenings' entertainment.

With modern tools, there's no geat deal of graft (hard work) involved. It's more a matter of working out the easiest way to do each job.

For example, cutting out the blades and the blade slots for the diffuser assembly shown here was done on a woodworking bandsaw and took about 10 minutes.

Only thing is, it's getting expensive in terms of materials. A big lump of aluminium like this costs real money.

So as an aside, I've started experimenting with a homemade forge to recycle aluminium scrap - It looks promising, I was able to melt down a pile of swarf and tiny offcuts to make a respectable ingot,

just using some scrap timber and barbecue coal as fuel. The turbine starting blower made an excellent bellows.

The hearth itself was just a loose circle of driveway bricks (known as 'pavers' in the UK). Some of these cracked with the heat but without any fuss.

For a crucible, I cut an old disposable gas cylinder in half (the type that is used for argon in portable welders)

I ran some tests on this compressor/diffuser assembly. I mounted it in the engine casing with a manometer attached so that I could measure the pressure. Then I drove it using an electric motor.

At 18,000rpm, I got a pressure rise of 5 inches of water. (with all the holes in the case completely closed off.) So that gives me a measure for the best the compressor can manage at that speed.

With the engine running, if I can get better than 18000 rpm at a casing pressure less than 5 inches, I reckon it should self-sustain. Anything less than that speed will result in the gasses being blown back through the compressor.

(18000rpm sounds like a reasonable idling speed to aim for)

Here's the rear of the compressor/diffuser assembly, with the drive shaft mounted. Note the oil feed pipe that injects oil into the (3) cooling air slots machined into the turbine shaft mounting.

Air and oil mist are driven down these slots by the engine compression and into the shaft tunnel.

This arrangement seems to work. After the first test run, the bearings looked slightly discoloured but not burned or coated. There was still liquid oil visible in the ballraces afterwards.

The combustion chamber - It looks a bit nasty in the photo because I didn't bother to clean off any brazing flux before running.

A couple of problems came up when building this - I didn't have the correct material (thin stainless) and had to make do with some 1mm mild steel

that was a bit thick to shape - especially the dished front. I tried spinning it in the lathe but gave up and resorted to bashing it into a hollow former with a ball pein hammer.

Then when it came to the holes, the drawings didn't agree with the text as to hole number and placement.

Some of the holes are supposed to be recessed in a hollow to form a sort of venturi effect

but the metal was too thick to allow this.

Still, it should be better than the old one anyway.

The fuel injector ring is mounted in place at the rear and injects fuel into 'sticks' (pipes) that project from rear to the front of the chamber.

This makes all the difference to maintaining a stable, torroidal flame in the front of the chamber.

Even at full blast, there was no sign of flame at the engine exhaust.

The burner ring being tested on propane. The feed pipe is 3mm steel and each nozzle is a 1mm hypodermic needle brazed in place.

The assembled engine with the outer casing removed. The thing sticking out the top of the casing is a brass nipple to measure internal pressure.

This engine was tested using the new impeller and a turbine wheel recycled from the old engine.

The starting speed was 5000rpm. When the fuel was turned on and ignited at the exhaust (I dispensed with the spark ignition), the flame fired back into the combustion chamber immediately.

I found that controlling the gas supply allowed me to vary the engine speed from 5000 to 16000 rpm. At the latter figure, the turbine exhaust began to glow red-hot.

These results were encouraging, 16000rpm is a new record and the speed control was excellent, but the engine still failed to self-sustain.

Taking away the starter air-blast caused the turbine to simply wind down.

I put this down to the turbine wheel itself, which doesn't fit the housing terribly well. The turbine housing itself is not of the best quality too. I made a couple of mistakes that left the housing out-of-round.

I need a new turbine wheel and back end (Nozzle guide vane) assembly

Efficiency

In theory, any gas turbine should work, no matter how badly made, if you can get enough heat energy into it. Thermodynamics says so.

The trouble is that all the thermodynamic calculations in the world won't tell you if a particular home-made turbine or compressor wheel is going to be 90% efficient or 9% efficient

and the efficiency of the compressor/turbine system determines the temperature that the engine runs at.

Below a certain efficiency level the necessary gas temperature is above the melting point of the components, or you can't supply enough fuel. Either way, it won't work.

I spent a lot of time trying to think of a way to measure efficiency of the compressor and turbine. But without building some sort of calorimeter device that can accurately measure the power supplied or absorbed at the drive shaft , I can't see a way to do it.

The obvious step of attaching an electric motor to the shaft allowed me to get some speed/prssure values that were interesting (suggesting that the compressor efficiency was just a little down on Schreckling's design ), but the motor power (current*voltage) was obviously being mostly wasted in the motor itself.

I'm not saying it isn't possible, it just isn't worth the investment of time and trouble. I may as well just keep experimenting to improve the efficiency of each component part.

The various construction books on the subject are little help. If you pick through the maths carefully it all makes sense until you come to the critical question of efficiency, then it all breaks down into assumed values and 'according to experiments' (not detailed)

The two main books, Schreckling and Kamps disagree wildly.

Schreckling gives an assumed value for his compressor as 70% efficient.

Whereas Kamps gives a figure of 0.86 for what he calls the 'pressure ratio' of the same compressor :-

2 . Cp . T[(P/Po).286-1] / u2

This is basically efficiency as defined by Schreckling(P37), times 2 so Kamps is saying the Sch. compressor is 43% efficient. Other values given are 65% for the T. Marbore and 1.16/2 = 53% for another, homemade.

Posted by

Anthony

at

07:17

0

comments

![]()

![]()

The new compressor

I'm pretty proud of this, My first attempt at using Carbon Fibre.

I got more resin on myself than on the wheel but it turned out pretty well in the end.

This picture is about life-size, its 60mm diameter. There are 8 vanes and they're simple radial paddles, with the inner slot height of 10mm reducing to 6mm at the edge .

That makes the cross-sectional area of each void constant as the gas flows toward the edge. (According to theory, no significant pressure/volume change takes place in the compressor wheel)

It's a little over-large but I can adjust it down during testing.

More Testing

By now the bearings were in a pretty rough state but I decided to go ahead anyway and get what life I could out of this prototype. .

I made up a temporary diffuser assembly and stuck everything together with string and masking tape.

When I turned on the blower (hairdryer) it was obvious things were not well. I couldn't get more than 1500rpm, accompanied by faint rattling and scuffing noises from the turbine..

But I fired up the propane gas anyway.

Speed went up to 9000rpm!

Unfortunately it became clear that at this speed, the faster flow of gas was shifting the flame position in the combustion chamber. Combustion was taking place right at the back of the turbine.

Eventually, the whole of the exhaust pipe aft of the turbine was glowing bright red. I didn't dare step round the engine to get a view of the turbine blades (forgot to set up a mirror). It would have been attempted suicide to get inline with that turbine.

Finally, with the turbine audibly rattling in it's bearing mount and speed dropping, I decided to call a halt.

Post Mortem

It's the end for this engine. The rear bearing has siezed solid and reamed itself a larger seat in the housing - about 20 'thou' oversize..

Things learned?

I definitely need to provide lubrication somehow and the combustion chamber is not good enough hopeless.

Fortunately, my back ordered copy of 'Model Jet Engines' (Thomas Kamps - Modeller's World Series) has arrived and I can see that the engine design given there is pretty much along the lines I have been experimenting with.

The rear bearing assembly is anchored by the turbine stator blades just like mine. In fact it's almost exactly the layout I had been sketching out for the next version.

The combustion chamber on the other hand is FAR more sophisticated, with air/fuel injected from the rear to set up and maintain a toroidal flow of the combustion gasses.

No question about it - I need to make a fresh start and build something more on the lines of Thomas Kamp's engine.

Posted by

Anthony

at

07:12

0

comments

![]()

![]()

Initial tests

First Test

First problem is getting the turbine up to starting speed. Schreckling says at least 3000 rpm is necessary.

Without much hope, but just to see what might happen, I borrowed the wife's hair-dryer to spin the turbine with a magnet taped to the turbine shaft

By placing a coil of wire close to the magnet I was able to generate a signal which I measured on a 'scope. It came out at 50Hz - just 3000 rpm!

So having run out of excuses, it was time to take the whole thing out into the garden and annoy the neighbours..,

Having no idea what might happen, and not intending to run the turbine beyond idle speed, even accidentally, I fitted a 36mb regulator to the propane cylinder and wedged the turbine between some high-density concrete bricks.

Oil was supplied to the bearings from a squeeze bottle.

First I spun the turbine up using the hair dryer (via a cardboard tube). Gave the oil bottle a good squeeze and opened the gas tap.

I tried to ignite the gas at the turbine exhaust but the air blast made it impossible. I was using a folded paper taper (spill) but it just blew out.

Ok. Turn off the hairdryer - as the speed of the turbine fell off I tried again.

It still refused to ignite, but as the turbine came to a halt, there was a dull 'pop' and the whole gubbins belched yellow flames out of both ends.

I hurriedly switched on the hair-dryer again (before it caught fire) and was rewarded by a lovely roaring sound and blue flame from the exhaust.

The flame held steady as the turbine speed rose. The noise wasn't excessive, no louder than a blow torch burner.

I tried removing the hair-dryer, but the turbine couldn't self-sustain and started to wind down.

Suddenly, there was another 'pop' but much sharper and high-pitched. The flame-roar went up in pitch - the sort of sound you get when a bunsen 'blows back' and starts burning at the bottom of the tube.

Obviously, the gas had been burning mainly in the exhaust region and had only just ignited properly back in the combustion chamber.

With the hair-dryer back on, there was a distinct increase in speed too, with a whining note beginning to be heard from the turbine.

I seemed to be getting some power feed-back from the turbine but it was still not self-sustaining.

I wound the gas tap fully open but got only a small increase in noise and speed. It was pretty obvious that the paltry 36mb of gas pressure wasn't pushing enough gas into the turbine - not surprising, its only a thirtieth of an atmosphere and the engine compression must be of that order too.

The turbine blades were now beginning to glow dull red at the tips.

I tried another squeeze of oil, which produced bright yellow sparks from the exhaust.

As I was standing, wondering what I could try next, I realised speed was dropping. There were no odd noises, just a gradual decline.

So I shut off the gas and let the hair-dryer run to cool the engine while I went to have a cup of tea and stop shaking..

Post Mortem

Although the casing was quite cool (about 15 minutes later) The inner parts were still very hot to handle. And it was pretty obvious what had gone wrong.

The rear bearing was glued solid with cracked oil. It was just a solid cake of carbon and tar.

I'm going to have to give a lot more thought to cooling around that rear bearing.

I cleaned up the bearing and tried another run, using a much lighter grade of oil, with the same result.

By now the bearing was in such a state, I decided to sacrifice it. I cleaned it, put it back in, and gave it another run.

This time with no lubrication.

It ran - and ran - and ran. After about five minutes, I got bored and shut it down.

It looks like this is the answer, at least temporarily. I don't expect it to survive long,

but this is only the first try and I've already learned a lot. There are lots of things wrong with the construction that I can improve. If I can get this even close to to self-sustain I will count it a major success.

I removed the gas regulator.

And I also made a couple of changes to the combustion chamber. Nothing radical - just moved the gas inlet pipe and burner ring to the inside of the chamber.

I made several attempts at starting before I accepted that I just couldn't get the flame to 'pop' back into the chamber.

It just continued to burn outside the engine

Eventually, I accepted that something was wrong and it wasn't just the extra gas pressure, so I stripped out the combustion chamber to do some tests.

I decided to make a test rig consisting of a steel tube and a nozzle for the hair dryer. With the combustion chamber mounted in that, I was able to see that there was nowhere near enough primary air entering the chamber.

The gas ring was apparently obscuring the air flow, something about it being on the inside of the air holes, rather than the outside seemed to make a big difference.

It's possible that with the gas ring mounted ouside of the chamber, the burning gasses could be passing round the outer and inner walls of the chamber

(maybe that's why the rear bearing was getting so hot?)

Anyway, drilling another set of holes in the annular plate made all the difference.

I also took a couple of days off to make an ignition circuit. I bought an ignition coil on eBay and wired it up to a 555 astable multivibrator cct. with a driver transistor (2N3055).

That saves a lot of hair-raising messing about with cigarette lighters. It also ensures that if ignition does occur, it's in the right place.

I reassembled the engine and tried again.

The combustion chamber behaved much better. But each time I got the engine spinning and ignited the fuel, the turbine began to foul the casing,

I stripped the engine and looked for rubbing marks in the turbine housing. They were all to one side, indicating the turbine was off centre.

BUT checking with a feeler gauge, it was pretty clear that the turbine was quite central, at least when cold. - So I took a 1/4mm off the diameter and tried again. And again.

And again... Eventually I had the turbine running with a clear 1mm gap all the way round but it still fouled the casing when it got hot. No way is that down to the turbine expanding.

Obviously, the whole rear end bearing mount is moving sideways by at least 1mm when it gets hot.

Back to the drawing board. But hey! - Who said it was going to be easy?

Mark 11

I completely remade the engine. This time, I made the central rear bearing support a single unit with the turbine stator.

The old turbine wheel was a bit undersized by now so I made a new one to the same pattern.

This time, I was able to get the engine to spin without fouling, even with the turbine and casing glowing red-hot.

But I still couldn't get it to self sustain.

I made a simple device to measure rotational speed using a reflective photodiode looking at a locknut on the shaft (It pokes out of the front of the engine)

and using the hairdryer to spin the turbine, I took a series of speed measurements.

With the compressor removed, cold speed was 4000 rpm. Igniting the fuel took that up to 8000 rpm at minimum throttle setting but increasing the gas supply made only a slight difference to speed with unburnt fuel coming out the back and burning in a big yellow flare.

Refitting the compressor and repeating the run resulted in a cold speed of 3000rpm and a 'hot' speed of 6000 rpm.

There was a very small throttle effect in that increasing the gas supply off the minimum resulted in a small increase in speed ~200-300rpm before the yellow flare appeared.

The conclusion I draw from those tests is that the compressor has no observable effect in increasing the airflow. In fact, if anything it's reduced. It seems that the turbine isn't supplying enough power, Or conversely, the compressor loading is too great.

It's interesting that the compressor restricts the airflow from the hairdryer and results in a lower 'cold' speed. I had expected it to act to some degree as a turbine in the airflow, obviously it doesn't.

In a way, this is encouraging - it shows I am getting real drive from the turbine, not only from the cold airflow but also from the burning fuel. So the turbine is behaving reasonably well and the combustion seems to deliver useful energy to the turbine (It isn't being completely wasted) .

In fact, the speed doubling effect of the burning gas suggests that the volumetric flow must be doubling so the heat is causing the gas to expand by roughly a factor of two.

That would correspond to a doubling of temperature (pressure changes are relatively small and can be ignored). So from (say) 290 degrees K, at ambient the temperature would be going up to 600 or so, which is 300 degrees C. Not unreasonable for an average temperature of the gas? The turbine is not glowing at all when running, so I think that's fair.

Sadly, I have to admit, I simply don't know enough about jet turbines to understand what is wrong.

There's only one answer to ignorance, I have to learn. I need a crash course on jet turbine theory. I will have to buy some books.

Later (much later)

As an aside, it looks as if all the gas turbine theory books have been written by Germans.

That's unfortunate. While they have a well-deserved reputation for painstaking accuracy, that same virtue makes them blind to approximation.

There is no German word for 'simple explanation'. Every text goes into minute detail over turbine/compressor efficiency and the effect of blade thickness/angle with the result

that the real 'nub' of the narrative gets pushed into marginal notes. The basic formulae are often stated as an afterthought, often in obscure, non-standard notation with no attempt to identify the parameters correctly.

After several days and several dollars spent on books, I finally have the answer. It's really simple.

The shaft power of a turbine or a compressor (same calculations but in reverse) depends primarily on the peripheral speed of the rotor.

It turns out that the impeller doesn't actually compress the gas in any significant way. What it does is to speed it up. Compression actually occurs in the diffuser when the gas is slowed again.

In simple terms, the K.E. of the gas as it exits the compressor is just m . vc2 /2 .

where vc is the compressor 'tip speed' and m is the mass of gas involved.

(This is a simplification because the real formula involves the scalar product of two velocity vectors, the wheel itself and the gas flow - but by happy coincidence, efficiency is maximised when these match, so v squared is a fair approximation)

The KE given to the turbine is a similar calculation, resulting in m . vt2 /2 .

Assume that all the power(energy) supplied by the turbine goes to the compressor. (at steady speed)

and we get: -

m . vc2 /2 = m . vt2 /2

Since the mass of gas entering the engine per second is the same as the mass leaving (conservation of mass) the factor m/2 cancels.

so vc = vt

The tip speed of the turbine MUST be equal to the tip speed of the compressor.

Furthermore, because they are mounted on the same shaft, they rotate at the same speed.

So they must have the same diameter

That's where I've been going wrong! My compressor diameter is 85mm compared to the turbine's 60mm

That means the compressor is demanding twice as much power as the turbine can supply at any given rotational speed (852 = 7225 : 602 = 3600 )

That's probably why the speed of the turbine drops so dramatically when the compressor is installed.

I hasten to add, before someone blasts me, because what I have said is based on one possible configuration for the gas flow, the resulting conclusion is not the only solution. It is possible to match compressor turbine of different diameters, but it isn't likely that the solution will hold for different flow rates. But this IS the reason why most designs for a model jet engine (or a turbocharger) have similar sized compressor and turbine wheels

I have two options. Make a new engine and turbine, or make a new compressor.

If this is going to be truly a home-made jet engine, I have to go for the second choice.

Having thought about the construction options: wood, metal, composites, It seems the easiest option is the most exotic.

I've never worked in carbon-fibre before but I know enough about the alternatives to doubt the feasibility of making a metal or wooden turbine.

(Yes, I know Schreckling used wood. But it was an exotic laminate and heavily reinforced with CF)

So I've bought a carbon-fibre student's kit

Posted by

Anthony

at

06:09

0

comments

![]()

![]()

A Homemade jet engine (The journey begins)

The 600 Watt vacuum cleaner that started it all.

It's made in China, where they obviously haven't yet perfected the technique of making poor quality goods that hold together just long enough for you to lose the guarantee.

It's so powerful, it nearly twists your wrist off when you start it. And instead of the usual plastic moulding, it boasts a lightweight aluminium compressor wheel of superb design and construction.

I put a strobe light on the spinning compressor and found it was rotating at 50,000rpm!

On sale new for about £20 - I got it for £3 from a car-boot sale.

The juicy bits extracted from the vacuum. (I'll use the motor for something else)

From left to right,

The diffuser vane assembly, which stops the air spinning after it is ejected from the compressor wheel.

This is plastic so it won't stand the temperatures - pity.

The compressor wheel proper - beautifully made from light gauge aluminium sheet.

The compressor housing - galvanised steel. Slightly corroded but still useable

Bottom left, the new diffuser. Made from 1.8mm aluminium sheet with vanes cut from a bit of shim steel and glued in place with epoxy. It's a push-fit inside the housing and the springy vanes hold it nicely in place.

Those vanes are designed to catch the compressed air that's spinning around inside the periphery of the housing

and direct it back to the centre while taking out the spin. The result should be a smooth flow of compressed air.

Notice there's one more diffuser vane than there are blades in the compressor?

That is a refinement that further reduces turbulence. If they matched up, the result would be a siren.

The internal parts.

Top row, the diffuser (again) and the shaft housing. This is made from a length of tube with a bearing housing brazed to each end. The spoked ring holds the housing centrally in the outer casing.

The diffuser assembly is fastened to the front of the shaft housing using three countersunk screws and holds the front bearing in place.

The rear bearing is allowed to float axially (partly to allow for thermal expansion).

Bottom row, the partially complete turbine wheel. (The blades need shaping). The rear turbine bearing assy. The main shaft, compressor bearing assy. and the compressor wheel.

Here's a shot of the partially assembled turbine shaft.

The turbine wheel is 1.8mm stainless, sawn to a circle, the blades slotted and then each twisted to 37.5 degrees.

I really didn't think I could do this:

The outer casing is constructed from stainless steel pipe, 100mm diameter.

But the turbine end is 64mm diameter pipe, So the casing needs to come down from 100mm dia to 64mm with a taper section.

I hacksawed a sector out of steel plate (1.6mm ss), which took quite a while and left me dripping sweat. Then I spent ages more gently pounding it over a steel bar with a rubber hammer.

I'm pretty proud of the result - a truncated cone that neatly joins the two cylindrical sections.

Here are the outer casing parts, ready for welding,

It will have to be welded, This part is likely to get too hot for brazing. The idea of the turbine casing coming adrift at speed doesn't bear thinking about.

The spoked ring that holds the turbine shaft is slighly larger than the casing so that it slides over it. (I cut a pice of the same pipe, split it and inserted a spacer.)

It will be bolted to the casing.

All of the dimensions were dictated by the size of the compressor wheel and housing and the available sizes of pipe I had in the workshop but it all worked out quite neatly in the end.

There's still a lot of work to be done. The turbine needs a set of stationary vanes too (mounted in the conical section of the casing) to increase efficiency.

Those turbine blades need to be shaped to an airfoil section and the wheel balanced.

(Expected speed is 20-50,000 rpm so any imbalance could be quite exciting.)

Then there is the combustion chamber, fuel feed and a continuous oil supply for the bearings...

Construction - Turbine stator assembly

Welding up the outer casing was a mistake. More haste : less speed.

I should have put in the rear stator blades first.

There's a bit of confusion over what to call this bit. Its a stator assembly really, sometimes (wrongly) called the diffuser which confuses with the compressor diffuser. Most people seem to settle on Nozzle Guide Vane assembly (NGV).

These blades impart a rotation to the exhaust gas flow just before the gas strikes the turbine blades, which just about doubles the efficency of the turbine.

The rotation is 'taken out' by the turbine with the result that the exhaust gasses exit pretty well straight out of the back end.

Only problem is that they are the very devil to fit. Slots have to be cut in the conical section of the casing. And these slots would ideally be curved so that the

stator blades can be curved too. Then they must be inserted precisely enough to provide an accurate location for the turbine shaft.

On the whole, a tediously fiddly job that would have been easier if I hadn't made access almost impossible beforehand.

The inner end of the stator blades form a ring that locates the tube that in turn supports the back end of the turbine shaft.

The tube also acts as a heat shield for the rear bearing (I got this badly wrong too, but more on that later)

Combustion chamber

I hadn't the faintest idea how to make a combustion chamber. But apparently, because of the high temperature of the burning fuel, most of the air that comes into the engine is used for cooling so that the turbine blades don't melt.

Everything I found on the subject suggested that about 20% of the air is used for direct combustion, another 20% is used also in combustion but also to help stabilise the flame towards the front of the chamber (by creating a vortex).

The rest of the air flows around the outside of the chamber and is introduced gradually into the hot gasses.

So my design was for an annular chamber, consisting of a ring and two tubes (inner and outer).

The whole thing is just stitched together with pieces of stainless steel wire.

The annular ring is pierced by 16 holes (6mm dia). Propane is injected into these holes from a 'gas ring' placed just in front.

The gas ring is just a ss tube, bent into a circle and pierced at 16 points to coincide with the holes in the ring. The tube is held in place by stainless steel wire, hooked into the ring holes.

The other (straight )tube visible just above the gas ring in the picture is the oil feed to the turbine shaft.

About 20mm along the inner and outer tubes is another series of holes. These are intended to inject air sideways into the flames, hopefully imparting turbulence and ensuring that all the available fuel is burned within that region.

At the exit end of the chamber there are more holes to allow the remaining air to enter the chamber, providing cooling.

Before mounting the chamber in the turbine, I tried some static tests, blowing air into the chamber which was mounted in a tube. When gas was added and ignited, it did seem to burn as expected, but there is no way to be absolutely sure how it will work in practice.

Posted by

Anthony

at

05:16

7

comments

![]()

![]()